I think that POM minimum wall thickness is 2.5 to 2mm? Don’t quote me on that. 7068 Aluminum can get down to 0.8 mm wall thickness I believe.

In this design the plastic part doesn’t contribute to the structure of the yoyo. For example if you bang the yoyo into the ground there won’t be any stress on it, so I think it can be made thinner than the usual recommended minimum wall thickness. Honestly the exact measurements don’t really matter at this point because I would have to talk to a machinist to figure out the precise material properties.

This looks really neat. No idea if it’s feasible or not but I like it

My design is done!

here are the specs:

56.0267009554mm diameter

53.00826 mm width

66.4347714427g

Bimetal

6061 aluminum

400 series stainless steel

congrats! keep it up

This looks lovely, nice work!

My only recommendation is to add a flat stop here (red squares) so that the “caps” can be pressed in fully to the set depth. Otherwise you’d likely have a pretty variable gap width after assembly.

The steel ring needs two flat sections to hold it on, one completely horizontal to hold the press fit, and one completely vertical to act as a stop when it’s pressed on.

Make sure all the parts have at least a minimum thickness for machinability as well - for aluminum alloys you’d typically have 1.0 mm to 1.6mm.

thank you!

That makes sense. How thin do you think the plastic part can be made?

what cad do you use?

I use Onshape. Make sure to add fillets to all those sharp corners so they wouldn’t cut someone. Also make sure everything is fully constrained. You shouldn’t be able to click on a point and drag it around. It should look like this:

Or make a finger laceration throw. Always an option I guess

I would suggest you watch the videos AtomicChessGuy sent you earlier. You’ll save a bunch of time rather than tweaking the design, asking for feedback and getting told the fundamentals again from these videos.

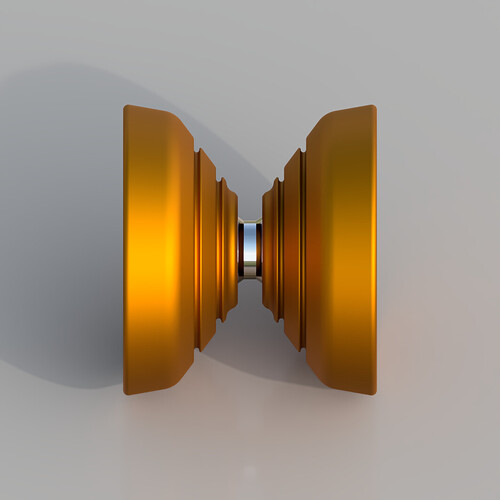

Specs:

Width: 48mm

Diameter: 56mm

Half Weight: 30.014gms

Assembled Weight: 62.929gms

MMOI: 14776

Axle: M4 x 8mm x 0.7

Bearing: Size C

Thoughts/Criticism?

If the string gets caught in one of the grooves, the yo-yo stops spinning, right?

I’m actually not sure. I think what would happen is that the string would land in a groove and begin to tilt the yoyo off axis but I don’t know anything for certain. Might be a fun yoyo to play with or it might be completely terrible.

It looks cool, but I would wait for reviews before buying one like it