To quote my third grader, “the power of ‘yet.’”

Well now Andy corners the market in mr85 based yoyo pads and maybe now mark has a new shop for the next weird mr85 thing he wants to do lol

I, for one, accept our new MR85 overlords

For context from this shop the RSO style pads it’s

$200 for 200 pads

$300 for 3,000 pads

$400 for 10,000 pads

The standard somewhat firmer pads from the factory Mark with MK1 uses had previously told him something like a 1000 pad minimum for a custom order but they seem to have changed that policy. The rep told me 20,000 pad minimum order for $1000

So for custom pads this is honestly the better deal. Plus the pads are in high demand from makers, folks like me, Pyro, and Keith. I figure at least some folks in the maker community will be happy to take some pads off my hands at cost.

Okay!! Honesty sounds a lot better than I thought haha!

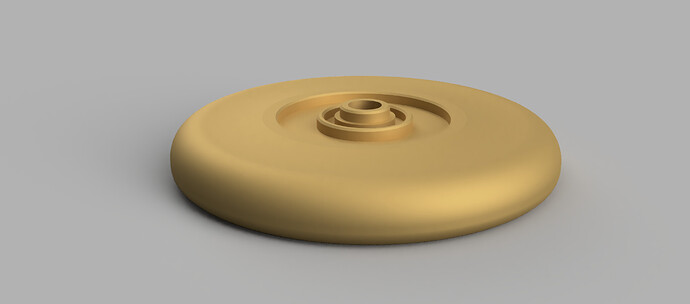

There was some interest so here are some renders of the first brass proto. It’s a modified version of the EDC, calling it the RIP (Rest in Pocket). It will also be a one piece fixed axle.

It’s very small (a little bigger than a quarter) 30mm diameter, 15mm width, weight should come in around 53-54 grams. The gap is only 2mm to handle the more slippery nature of metal axles, and to accommodate thinner string.

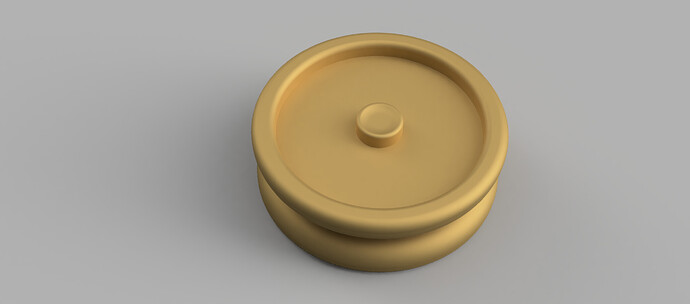

Renders of the second brass design. This is The Pocket Watch.

It’s 38 mm diameter, 15 mm wide. 2.3 mm gap, MR85 bearing. RBC style pads but RSO landing pad shore. Schmoove moat.

No deets on packaging, there might a clock engraving, this one is a ways out from production comparatively.

Both will likely be very small runs. (40ish units to guess). Going beyond protos will depend on if I make back at least what I spent or close to it on the EDC lol.

The fact that you sent these designs to shops and got puzzled and confused reply’s only makes me want one more

I mean, the obvious answer would be a hinged clamshell…

You’re killing me with both how wild these throws are AND their packaging!

Here are a few replies I saved.

Shop from Mexico that tried to make one. Their state of the art equipment can’t handle a 2mm gap.

A shop from the US that noped.

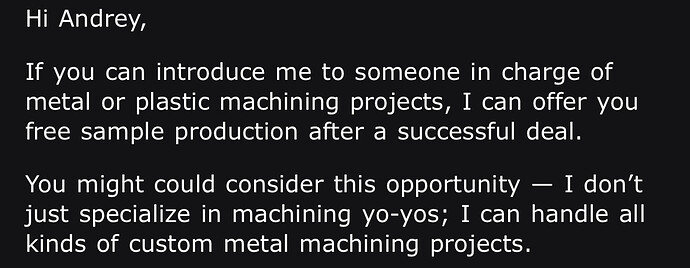

This is a shop in China that wouldn’t do a prototype run unless I joined a pyramid scheme and brought them someone else who needed parts machined.

I like the way you think. I haven’t designed anything hinged yet. Could be interesting.

Oh snap FedEx just notified me that they picked up a 7 kg package in China for me. Looks like the EDC yo-yos will be here before the tariff cutoff.

Yessss!

The last one had me dying ![]()

Yeah, having a tiny bit of machine shop experience, I’m not surprised nobody wants to try a 2mm gap. You’d probably need to use a parting tool, and standard parting tools are usually either 2mm or 3mm wide. But, they’re not really designed for that, and the cut ends up being sightly larger than the tool (runout, imperfect alignment, etc.). And beyond that, you’d typically want to make a rough cut and finishing cut on each side/wall, which there’s no room for. With a custom narrower parting tool, it would be more challenging since it wouldn’t be as stiff.

Sounds intriguing. I’ve been struggling with finding RBC pads for projects, so this will be a big help