I should probably add that this is an unresponsive design, since I normally don’t do those so I figured I should give people a heads up.

Printed some TPU rimmed responsive throws this weekend. Very surprised at the variability in stiffness between different colors of the same brand TPU. The white is actually GITD (from CCTREE), and is very stiff, which I think is to be expected for a filled filament. The brown is Hatchbox, advertised as 95A. The rest are all Overture standard TPU, also advertised as 95A. Same design and same print settings on all of these, with the outermost ~6mm having two walls and 12% gyroid infill. The red, purple, and brown all have enough flex that I can indent the outer rims pretty easily with a single thumb. The others I couldn’t indent even using both thumbs and pressing as hard as I can. There’s also variability between the flexible ones, with the red being the least stiff. I’ve always known that the dyes/pigments influence the material properties to some extent, but I did not expect the differences to be this significant. Just thought I’d throw this out here, especially for others playing with TPU.

Spaceballs the Yo-Yo printed!

Build notes: The threads were not very easy to get to work - had to sand things down a bit, taking far longer than I thought it would. Maybe there was some arcane step with an industrial sized hair dryer I missed. Also, the MegaMaid Schwartz rings didn’t translate to Bambu Studio, so I had to add my own modifier to set the material type for the SS infused filament. I used 85% gyroid infill to give it some weight. It’s not what I’d call stable or long spinning,but it works!

God willing there will be a second one - Spaceballs the Yo-Yo: The Search for More Filament.

With Yogurt! ![]()

Good to know about the issues with the threads. On my prints they came together pretty easily with no resistance, but I might be able to make a looser tolerance version with more accommodating threads.

You might also try lowering your print temp by ~10 degrees and find the threads work better as well, but that’s only assuming the issue is a little over extrusion preventing easy threading.

The kids love this one ![]()

I’ve found Spaceballs the Yo-yo is quite fun to throw on non-plush carpet - spins kinda like a top with some odd motion, but you can lead it about pretty easily with the string. I’m betting there’s a subgenre of throwing to be uncovered there… and worst case you can get your Schwartz twisted trying a dna bind.

Also just saw a trailer for the next spaceballs movie (The Schwartz Awakens) in 2027! Way to get in on the hype early!

I like the way you think! I think I’ll try making one of these out of TPU, it would be like a yoyo made from two bouncy balls. ![]() TPU is really durable so you could walk the dog and bounce it. lol.

TPU is really durable so you could walk the dog and bounce it. lol.

Hey I didn’t see this until now, this is cool! I assume you can do table top tricks like with a Capsule or Easter Egg? I love the filament you used for the blue! I don’t have any cool filaments like that.

I’m not sure I’m skilled enough to do table top tricks but I assume you can. Sounds like SethBurgess has been doing similar floor stuff.

Thanks! I subscribe to two different filament subscriptions from proto-pasta so I get 3 kg a month from them in surprise formulations so I always have a lot on hand. The blue is Night Before Blue and the silver one is Atomic Age Gray.

It skips around a lot on hard surfaces for my print, but works well on a carpeted surface assuming the pile isn’t too deep (the carpet squares in the office seem about perfect). Me being able to actually do tricks is probably overstating things, but that’s a skill issue rather than a yoyo problem.

I did it lol

Took about 2 weeks because of just printing problems but it was totally worth it.

My take on the Duncan professional yoyo or more commonly known as the Duncan coca cola yoyo of the 90s

Now available on my printables page

https://www.printables.com/model/1352661-professional-yoyo-by-cutting2crew

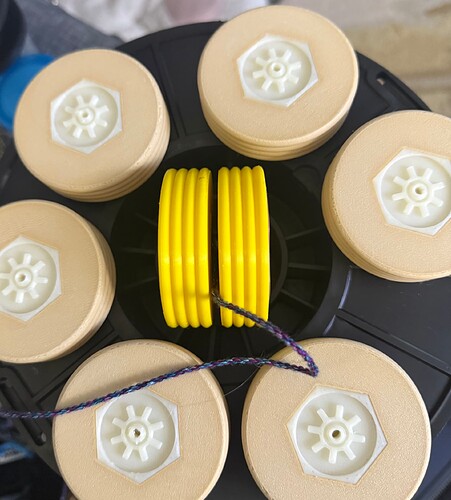

I now have a contribution to the TPU outside inner solid plastic bearing seat discussion.

I made this pancake stack yo-yo using TPU on the outside and a polycarbonate printed bearing seat. It’s a hex shape to help keep it in place. I bonded the pieces together using 3m scotch weld which I found on Amazon. It also worked great to bond polycarbonate bearing seats to wood fill pla.

I had been thinking about doing a square insert hub to make my build-your-own yoyo. The hex is a good idea though.

Moved on from waffles to pancakes, huh?

Yes lol someone made a joke about pancake tramplers in another thread and I had to make it a reality.

And then it turns out they are really fun to make because I can make the syrup in all kinds of whacky fun colors and it looks really cool so I’ve been churning out a mountain of them lol.

Cardi B!

Yes. I did have this thought ![]()

Playing my third take inspired by the OneDrop Laguna. I’m not super thrilled with the print on this one but it’s also one of the smoothest players I’ve ever printed so ![]()