Just in case you didn’t already solve this dilemma, I will share a few things. What I’m gonna share is specifically, and only my opinion based on what I see and what I dealt with. This isn’t the only view or necessarily the most accurate view or necessarily the only course of action, but here goes.>

First of all, nobody stepped on that yo-yo. Some genius put it in their pocket, probably back pocket and sat down on it.

…. if it was mailed to you like that, and the package has no damage to it and the yo-yo was packed well that would pretty much be impossible for the yo-yo to be like that. It would also be pretty much impossible for whoever put that in the package do not realize and recognize that that sucker was jacked up. So there’s that, lol.

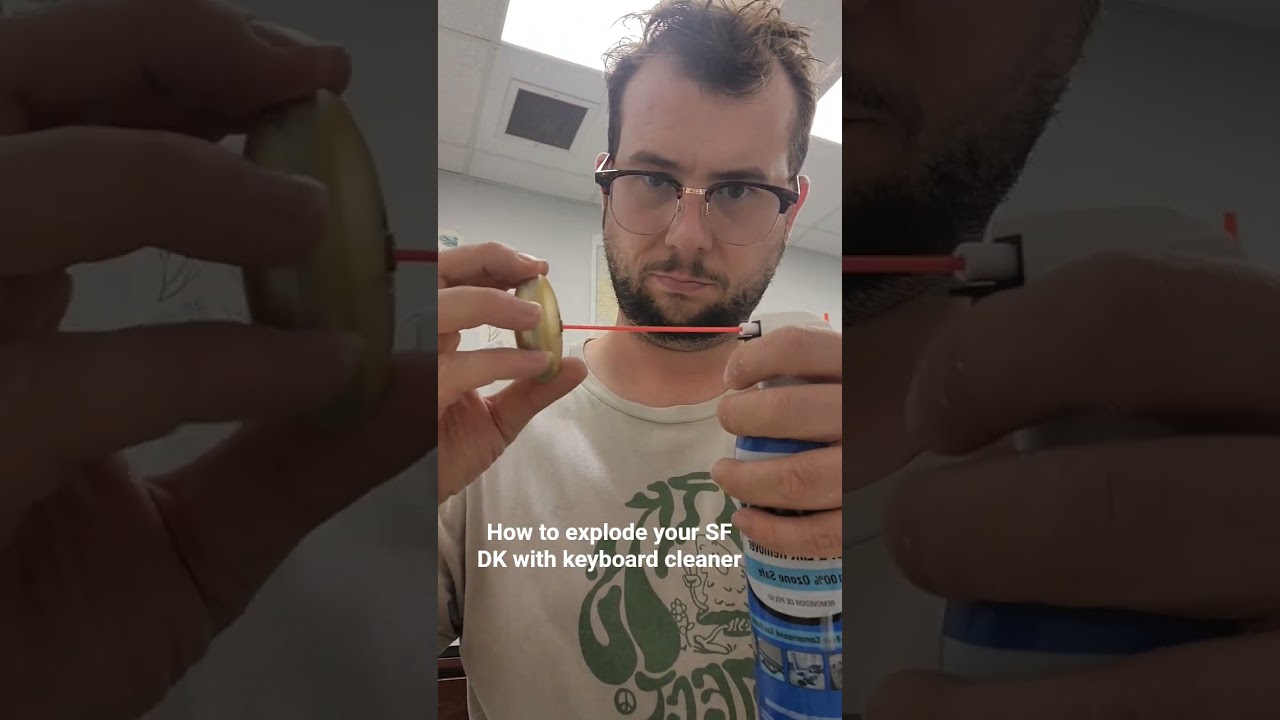

Regardless, you didn’t need to take the yo-yo half apart. And you certainly don’t wanna tap on it or pound on it or do anything of that nature.

Most obvious that you will need at least one or two replacement axles. The first reason being the axle in there may be a little screwed up. I can’t tell from the image? From what I can see the axle doesn’t really look bad because it looks straight just at that angle, which means the half itself is the thing that has been primarily compromised. That being said, even though the axle is much harder than the body material and that hollow construction of the yo-yo half literally lends itself To that sort of damage, it is possible the axle if ever so lightly tweaked it’s still gonna be part of the problem. In other words, let’s say, you square up that body to an amazing degree of success, if the axle still a little funny, the yo-yo was gonna spin a little funny.

The best way or pretty much the most accurate way of bringing that yo-yo half back into the proper alignment would be to chuck the axle up in a lathe and literally very very carefully grasp the half and bend it back in the position. This is where you need a couple of axles because you need to take out the existing axle, each step of the way and screw in a good axle and then chuck it up again in the lays and spin it slowly, possibly with a dial indicator on the side to see where you’re at. If you had the opportunity and ability to use a tile indicator, then having the half in a two pieces would turn out to be an excellent idea. Simply because you could put the indicator on the flat edge of the inner half to indicate run out.

The good news is aluminum by nature of characteristics, does not work harden easily. Metals have what’s called point of elasticity. The point of elasticity means something can be moved in one direction or another to a certain degree enable it will rebound to its original form. A good example is a metal coat hanger. Grab one end in each hand slowly flex it like a bow and arrow and then let it go. It’ll bounce back at least pretty much. Then decide to get an attitude and bend it until your wrist is almost touch then let it go. It’s not gonna bounce back because you’ve questioned the metal beyond this point of elasticity.

If that aluminum half is just spent a little bit as a result of some fat rear end, sitting down on it, it’s possible that is it is not locked in that angled position and is still malleable enough to be carefully returned to squareness.

If…… If even though it only looks slightly bent, elasticity has been compromised to the point where there’s a slight work hardened area, then you will not be able to return it to perfectly square position. When metal is bent in right at the bent point, the metal gets hard, when you try to return it to its former position, the hard metal won’t bend, but the soft metal peripheral to the hard metal will follow it.

I don’t wanna turn this too much into a like a technical structural theory manual. But nothing here is very complicated.

Somebody sent you a yo-yo that was bent already probably from somebody sitting on it. It’s possible as long as a metal hasn’t been compromised by being moved too much, it shouldn’t be that tough to move it back. It just takes the right touch to do it.

If you’re careful, you should be able to do it if the metal is not molecularly locked at that angle.

If you’re not too handy, or you don’t have a light touch and you don’t have the right equipment, then you might as well just put the yo-yo in your pocket and jump out of an airplane, parachute, optional.

If you haven’t already fixed it and you’re not bold enough to try because you’re afraid you’re gonna jack it up, you can always send it to me and I’ll do what I can to fix it. I’ll even make a video of me fixing it and everybody can get something out of that that may be interested in watching metal move.

Just like any surgical operation, there is a chance the patient will die on the table. But that doesn’t keep people from operating, does it?

If you try this yourself, you will need to go to a hardware store and get a couple small nuts that you can use to lock the old axle so that you can unscrew it. I think I have a video on my YouTube thing about that too, locking up an axle by locking two nuts against each other.

I charge nothing to fix yo-yo’s or at least to try to fix them. I’ve never charged anything in well over 20 years. And I always pay for return shipping out of my own pocket. It’s just something that I do.

PS…. Something else I think is important to mention. It may not be the brightest idea to just try to bring the damage back using the axle itself. As I had mentioned earlier, you chuck the thing up in a lathe and then carefully try to bend it back in position by grabbing the body, and then indicating it a little at a time. The metal used in those thin aluminum shelves is actually pretty soft metal compared to other metals that could sustain the same type of damage. So it is possible that by just using the axle as leverage that the metal will move back to its original position. But since there’s more metal to move Peripheral to the axle hole, it’s possible the axle will bend before the metal in the bearing seat area trues up.

considering that it may be necessary to mount a spindle with the appropriate axle into a lathe and then screw the half onto the spindle. I work in the afternoons, but when I get home tonight, just in case this dilemma is still an issue. I will show you guys what I’m talking about.