Wow - those are some chunky rims. That should check the “Rim Weight” box.

In this case the shmoove really removes weight in the center allowing more to be put at the rim without increasing overall weight. Still useful but I can’t see it doing much to reduce drag. ![]()

@Afkor I updated the design with a concave spike and made it more angled. Is that to your liking?

Looks good! I’d say make a couple more slight variations along those lines and then do a vote keeping in with the poll theme and that’d be sick. Maybe having 3-5 designs to vote on would be ideal.

Production version of the Spyglass does this too. It lets you adjust the profile/cup separately in some cases. Otherwise those two areas end up being locked to the same shape, or you add extra weight where it isn’t needed.

Been trying to make different variations on the first version I made however I have been really struggling to come up with difference that are great enough to make a difference. Does anyone have any ideas on what variations I could make?

I would buy this. Great job.

It doesnt technically follow the polls but I’d be intrested in see the same design specs but made for different materials ie polycarb, delrin, stainless, ti

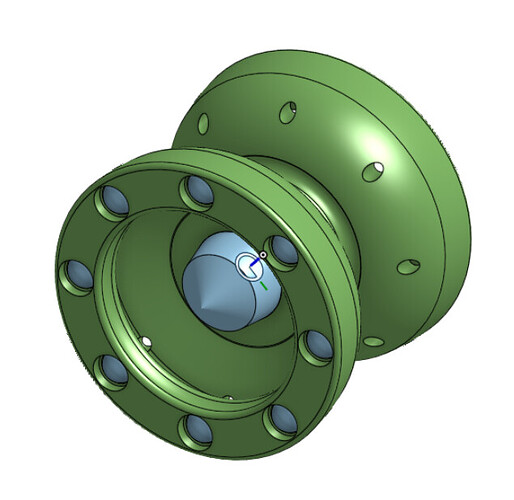

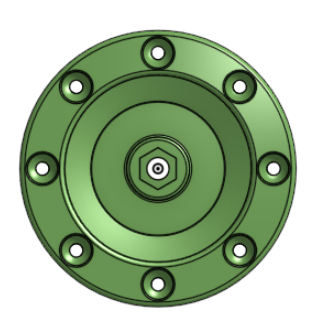

I made a 3d printed yoyo with these specs just for fun. Haven’t got to print it yet because I am out of town. Plan to get a FD Stem system and adapt the design for that too. If people are intrested I can post cad pictures.

I would love to see the pictures of the CAD!

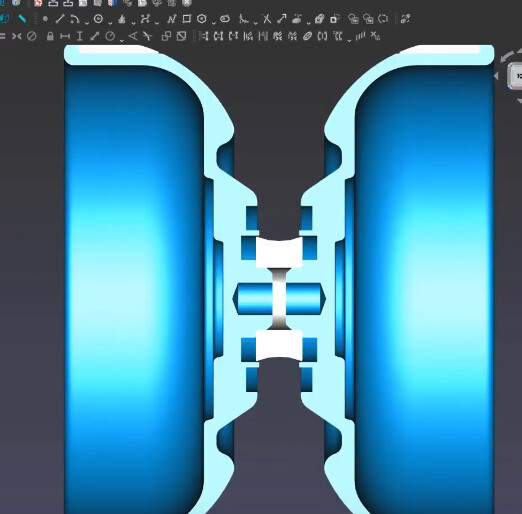

The hub system I use makes it tough to do a spike because it uses nuts to hold the halves together. Also uses 6mm balls to add weight without making the walls extremely thick. I haven’t modeled the nut and axel so that changes the MMOI and other things but not by much because they lie so close to the center. Hub is press fit but needs to be tested. The holes in the body are to remove the balls when a design inevitably fails.

Diameter: 54mm

Width: 44.1mm

Mass: ~63 g

MMOI: 24305 g/mm^3

Wow! This looks awesome! I would love to see this printed.

I’ll print it some time next week and update you!

Wow, that looks really cool! Definitely keep us posted whenever you get time to print it.

Plays great! Overhang is too much in the cup that supports don’t totally help but it doesnt affect play. The smoove groove definitely isn’t made for 3d printed yoyos because it just adds more friction but it still play really well imo. Worth losing one july.

Edit: Also I will update the design for the FD stem system when I get them in and I’ll post them for anyone else that wants to print.

The new one with the FD Stem basically looks the same. I had to imbed the bearing seat into the yoyo and basically considered that gap the smoove groove. Haven’t printed it yet and probably won’t unless other people are interested in printing it themselves, then I’ll print and test it to make sure it works as intended.

Hardware: FD Stem and 16x 6mm SS Balls.

This is really cool I don’t mind printing and testing myself I have a spare stem system I picked up recently.

I need to get a d and a size stem at some point too

Thank you! I’ve printed about 8 different yoyos for the stem system now so it should work well depending on the precision of your printer. Mine can get about 0.1mm tolerance which is what I apply to most of the areas that interact with the hub.

Here is the google drive link to the stl and step files:

https://drive.google.com/drive/folders/1wV7QI9vn9ToJPWHetfL5u5fXBaI-WO1N?usp=drive_link

Here are the ball bearings I use for weights:

6mm - 200 pieces

6mm - 100 piece

I figured this isn’t against the rules because its not an item YYE offers. If it is, feel free to remove the links. If the links have been removed, shoot me a message and I’ll send the links through PM.

If anyone prints one tag me! Also if anyone needs help or has issues with the model, let me know.