Thinking I’ll send V1 and V2 along maybe?

Looking pretty dang fun!

OK. So. Anybody who’s in Vegas can try out the Queen V2 as well as both versions of the RippleDrop. Everything is in the mail to arrive tomorrow. Go find @Obstinate_Yoyo in the afternoon!

Oh btw I reopened the order form, if anyone wants in. Same price break points as before.

Currently at 25 orders.

So cool seeing the process.

I need to get the units back to play around with them some more, but I think the V2 units are probably a little too mass-y on the throw. I tried to make them a little better for 1A style string tricks and I think I did the job a bit too well. Guess I’ll be making a V2.1 to play with the amount of rim weight.

Im close by. Maybe able to be a play tester…

I’ll be headed south Wednesday night for Anime Expo. I’ll be headed north on Sunday at some point. I’ll have at least one of the Queens with me on my way north.

I got to try the queen bee at nationals and I can confirm the queen bee can do rancid milk, it was quite fun.

How did you like the mass? I wanted to reinforce the idea that it could be stable for string tricks despite the narrow gap so I gave it a bit more oomph in the MMOI department compared to V1. It spins super stable and for a good long while now, but I personally feel like I overdid it.

That is a fine line to walk…

Ill DM you about Sunday. Maybe we can meet up.

OK. So. Now that anime expo is over and I’ve had the V2 units back for about a week to toss around and evaluate I am working on more units that will actually get sent out to people.

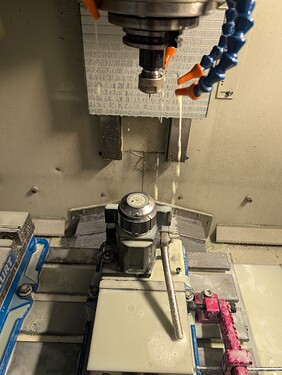

MACHINING UPDATE

Looking at the first units actually being ready for shipping next week to week-and-a-half, though I need to dig the laser marker out of the shop mess so I can get serials into the BPT wells. Keep eyes out in the places you indicated preferred contact. I still need to grab shipping info from everyone who ordered and collect rest payments.

Primary focus for the next couple cutting sessions is getting stock prepped so I can focus on running units one after another. Shouldn’t take more than a couple nights’ work with the way I currently need to do it, I hope. The unfortunate reality of my current setup is that stock prep is annoying and slow.

I’m waiting on a new tool that might help with it in the lathe, but that’s still just kind of a bandaid solution in terms of speed. The proper way to go for the future will be to rebuild the cold cut saw we have. I can’t use it for this currently because it doesn’t cut square to the table, but the moment I can it’ll 10000% be the way to go for stock prep in all cases. Problem is there’s so many other things I’m doing during the day that I don’t have the time to stop and fix it >_>

DEVELOPMENT UPDATE:

Like I figured, there’s gonna be some stuff I gotta figure out so that I can get these cut efficiently.

Current successes:

-

Form is great for the most part. The collet holding I designed lets me haul butt through the material when roughing and keep things mostly on target. I didn’t try baking them halfway through like I have some of the unresponsive things I’ve done lately, but I don’t think it’s going to matter much with the geometry of the surfaces involved.

-

They’re coming out PRETTY. I have a new finishing strategy I’ve worked out with a ground and very sharp tool that doesn’t mind the titanium much at all, and that should help keep things nice and clean. The spindle still needs a rebuild, so there’s still a bit of surface irregularity visible, but it’s not bad at all. The match line issue from the V1 is all but gone in the dimensional sense, though it’s still visible because physics.

-

The mill fixturing works really well. The X, Y, and Z location is repeatable to within like .0001-.00015 based on the measurements I took after installation, and the ease of just throwing a lever to fixture and release is a huge relief. It should keep the BPT pockets incredibly consistent.

-

All deburring works as intended. My personal V1 unit ended up shifting just enough with the old fixturing that I have a pretty bad burr on a couple of the surfaces inside the BPT that I notice fraying of strings. All the edge break chamfers in the V2 units are very clean and finger/string safe, which is nice.

Current issues to solve:

-

They’re HEAVY. Both V2 units I cut ended up being ~4g overweight. That’s pretty huge, but I can blame a bit of it on my getting them done at like 4AM. I meant for these guys to be 58.7g, they ended up being ~62.5. As a result they run ridiculously stable for 1A but hit pretty hard on the recall if you’re not expecting it. I’ll be running down some dimensional variances as quick as I can to try and get things more in line with the design weight, but I may need to adjust the design to pull MMOI down a hair if they stay massy when properly cut.

-

There was one place where a burr ended up sticking around. I think it’s down to my programmed path not taking a tool radius into account properly. The same issue also may have messed with the form a bit and contributed to the added mass.

-

Responsiveness may end up on this list but we’ll have to see. I equipped the two units I sent to Vegas with the center trac bearings, and they ended up being incredibly unresponsive. I tossed a bit of vaseline onto the pads to try and fix the issue, which worked pretty well provided I used a specific string that seems to work better for responsive play. When I got the units back I swapped to a regular flat bearing and the issue went away entirely no matter which string I use. I need to make sure I understand the issue properly, so I plan to confirm this dichotomy with fresh and clean pads.

-

Time is still an issue post cup roughing. I still need to work on getting the total cycle time for these guys under an hour. I saved myself roughly a half hour, which is nice, but there’s still work to be done.

LIFE UPDATE

Remember that original delay back in February when I just kinda dropped off the map and had the family medical happenings? Well that was me and my wife finding out we’re having our first kid in October. Took a bit of time there at the start for just needing some extra time together and such. 6+ months in and we’re finally ready to be public about it, so I figure I can finally explain that first hiccup. Should be a trip!

Congrats on the great news!

Excited to see the update, Congratulations on you two expecting! I am sure we all are understanding, and i for one know life gets in the way! You are doing great with communication in my opinion

I’m like 2.5 months late at this point and I haven’t heard a single complaint. I’ve had like 2 people on other platforms check in to see where things are at?

Genuinely very surprised at the patience from all of you. I really appreciate it. I HATE being late on something I’ve taken deposits on, so I really appreciate the lack of additional stress around it ![]()

Congrats on the baby on the way do whatever you need because family always comes first

I mean I expect to be pretty much absent from most life things after the first week or so of October, but prior to that I should be business as usual.

lmao so I decided to finally go gut check how far past the max ideal I’m actually pushing my current parting blade. Turns out I’m out like 1/2 inch past where I should be. No wonder the blade skews like .03in off square

I’m hoping it’s a girl (I have 2 and they’re the best) and her nickname lands on “B”. Congratulations on life’s greatest gift.

Score 1! We found out with the genetic screens pretty early on.

I’m 1 of 5, the 3rd of us to have a kid. I’ve got 2 nieces from my older sister, one neice from my younger sister. My older sister is pregnant with her 3rd but hasn’t gotten any tests done yet. We’ll see if the streak is broken or not lol

The one thing we aren’t sharing early with anybody is her name, but I can confirm it does not begin with B.